Keeping a Pulse on Printed Electronics

July 23, 2014

Inland recently had the pleasure of sponsoring and attending the Gravure Association of America’s Printed Electronics Symposium. This two-day event covered everything from interactive product innovation to the security and protection of functional printing.

Sound like some creepy science fiction novel? Well believe us, it’s not.

In all reality, it’s predicted that the demand for active and intelligent packaging in the U.S. alone will grow 8% per year – totaling a whopping $3.5 billion in 2017. That’s well above total packaging demand growth (according to the Freedonia Group).

With numbers like that sneaking up on us all, we thought we’d share with you a few interesting tidbits from the symposium:

1. Interconnectivity is key.

We all know consumers are more connected now than ever before – especially when they hit the store aisle. And while QR codes are cool and all, trends are showing that consumers want more automatic connectivity. But not just any flashy, “look-at-me” connectivity – they’re looking for connectivity that gives them access to useful information; whether about a product, a brand or a related topic.

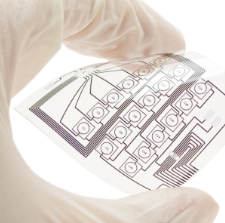

That’s where printed electronics come into play. Whether listening, measuring, calculating or translating, there are a variety of ways printed electronics can gather and share important data. A great example used at the symposium was a football helmet. Take what is usually a product used for protection only, incorporate printed electronics – and voila! You now have a device that can help us better understand the impact to the head, where the blunt of the hit was taken and other data to help diagnose the injury. As this avenue for “needs-based” information grows – on and off the field – so will the opportunities for brands to incorporate printed electronics.

2. Brands want the buying trends.

Sorry consumers, printed electronics are not all about you… Or are they?

Many brand owners are showing just as much interest in intelligent packaging primarily for the same reason as consumers – more information. By designing intelligence into packaging, brands can discover more of the market and buying trends they’ve always wanted. For example, what type of packaging is more appealing, where in the store are consumers more inclined to buy and who came first – the chicken or the egg? Errr, okay, maybe not that last one.

By further advancing printed electronics many of these capabilities are within arm’s reach. Now it’s up to the industry to conceptualize it – and give brand owners a first-hand experience of their product paired with printed electronics. Which leads us to our final point…

3. Technology is headed in the right direction.

Printed electronics have a come quite a ways since they first started. From high-resolution printing to thickness control, many of the processes and materials needed for intelligent packaging are falling into place. We all know technology continues to advance – and that means good things for intelligent packaging. The next step in this process is developing a seamless transition. Is your brand team up for the challenge? Is your supply chain fit for such requirements? Logistically speaking, can brands manage it efficiently? Many of these questions and more are starting to be discussed amongst brands intrigued by printed electronics – and we like where their heads are at.

So keep your pulse on printed electronics and intelligent packaging, because they’re undeniably alive and well… (queue the sci-fi music).