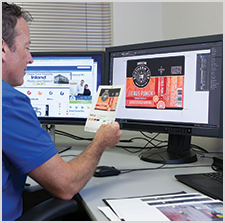

Behind the Scenes: Customer Graphics Coordinators (CGCs)

June 26, 2020

Is it just me, or in the world of printing and manufacturing, are there endless acronyms that we need to remember? Well, here is one more for you—CGC. At Inland our CGCs, also known as Customer Graphics Coordinators, are the all-stars that are the forefront of the artwork process. But before we get too far into their story, let’s start from scratch with a glimpse behind the scenes of Inland’s artwork frontline team.

Who?

Inland has over 400 employees across our four facilities. We have a team of four CGCs who are the face of the artwork team working directly with customers as they start building their artwork. Our CGCs have over 70 years of collective graphics experience, 34 specific to the packaging industry. The CGCs are the experts. They know the ins and outs of all the prepress and press specs and are responsible for communicating any concerns with the artwork when it comes to printability.

What is CGC?

As mentioned, the CGC team is the first to get their eyes on the artwork we receive from our customers. Their responsibility is to review what is provided by customers, to ensure all the pieces of the artwork are included in the files provided. Once all the pieces of the artwork are received, it is time to dig deeper. The CGC does a thorough review of the artwork to ensure that it has been built to Inland’s specifications. Our specs are black and white, but the CGCs use their expertise to decipher what is a major concern and needs to be addressed vs. minor concerns that may not impact the final printed product.

A few of the questions that our CGC team asks are things such as:

- What type of substrate is this label running on?

- How many inks are in the artwork vs. how many are available on press?

- What type of coating is used?

- Are there aspects of the art that need to be adjusted to achieve the result the customer is looking for?

These questions are all considered and answered before sharing the artwork with our prepress technicians. Our technician team physically “works” the files to get them print-ready. When artwork gets to their computers, they have all the information needed to process through our system to provide art-ready files to our customers for approval.

Why do we have a CGC?

You may not know this, but the CGC position hasn’t always existed here at Inland. Two years ago, the CGC position was created as a resource to our customers to improve the upfront artwork process. The vision for the position was for these individuals to be highly skilled and educated in our prepress and production processes to better serve our customers. The success of our customers’ graphics start with our CGCs.

Much of what we talked about above, is rather base level in terms of what our Customer Graphics Coordinators handle. The CGC team really shines when they can guide our customers through more significant changes.

- Is there a new container being used?

- Is the material changing?

- Is this a new label type?

- Is there a new dieline being used?

- Is this a redesign of the packaging?

These situations are when the CCG’s knowledge and background of our processes as well as our customer’s product set us apart from the rest. As we’ve mentioned, the CGCs are there to work alongside our customers to produce the perfect packaging from day one. This role has truly helped push new products and labels through the system efficiently, quickly and problem-free. It is never too early to reach out to our Customer Graphics Coordinators because in the end, the upfront conversations will pay off. We don’t want a redesign to be scary or daunting, we want to be by your side from start to finish.